step 1

Initial Discussion

- Understand customer utilisation and performance requirements for EVs to be developed

- Use advanced simulation techniques to model the vehicle's behaviour, performance and energy consumption

- Agree on the scope of work and specifications with the customer; obtain a signed Statement of Requirements (SoR) before proceeding to the development phase

step 2

Vehicle Integration and Testing

Alpha phase

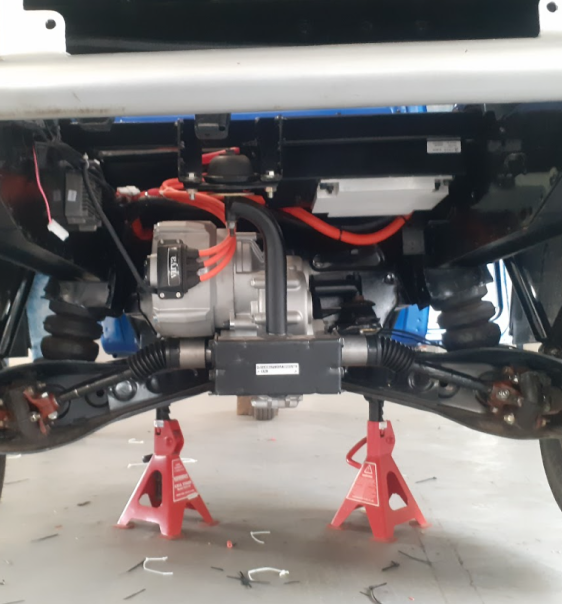

- Design EV architecture at vehicle level to ensure optimal performance

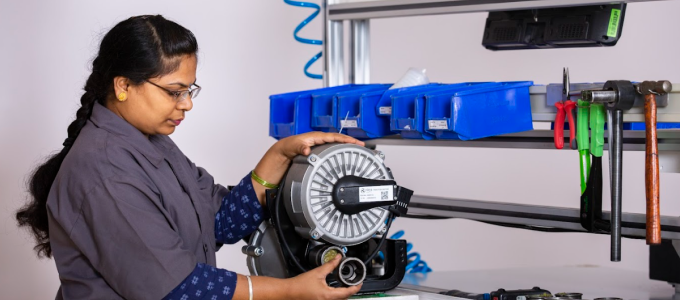

- Develop and test various components to ensure seamless functioning of the EV system

- Tune vehicle performance to achieve desired results

- Conduct joint performance testing with the customer and get signoff for the EV system

Beta phase

- Finalise the architecture of the EV system based on Alpha signoff by the customer

- Integrate battery with the powertrain

- Fine-tune software to ensure seamless operation and optimal performance of the EV system